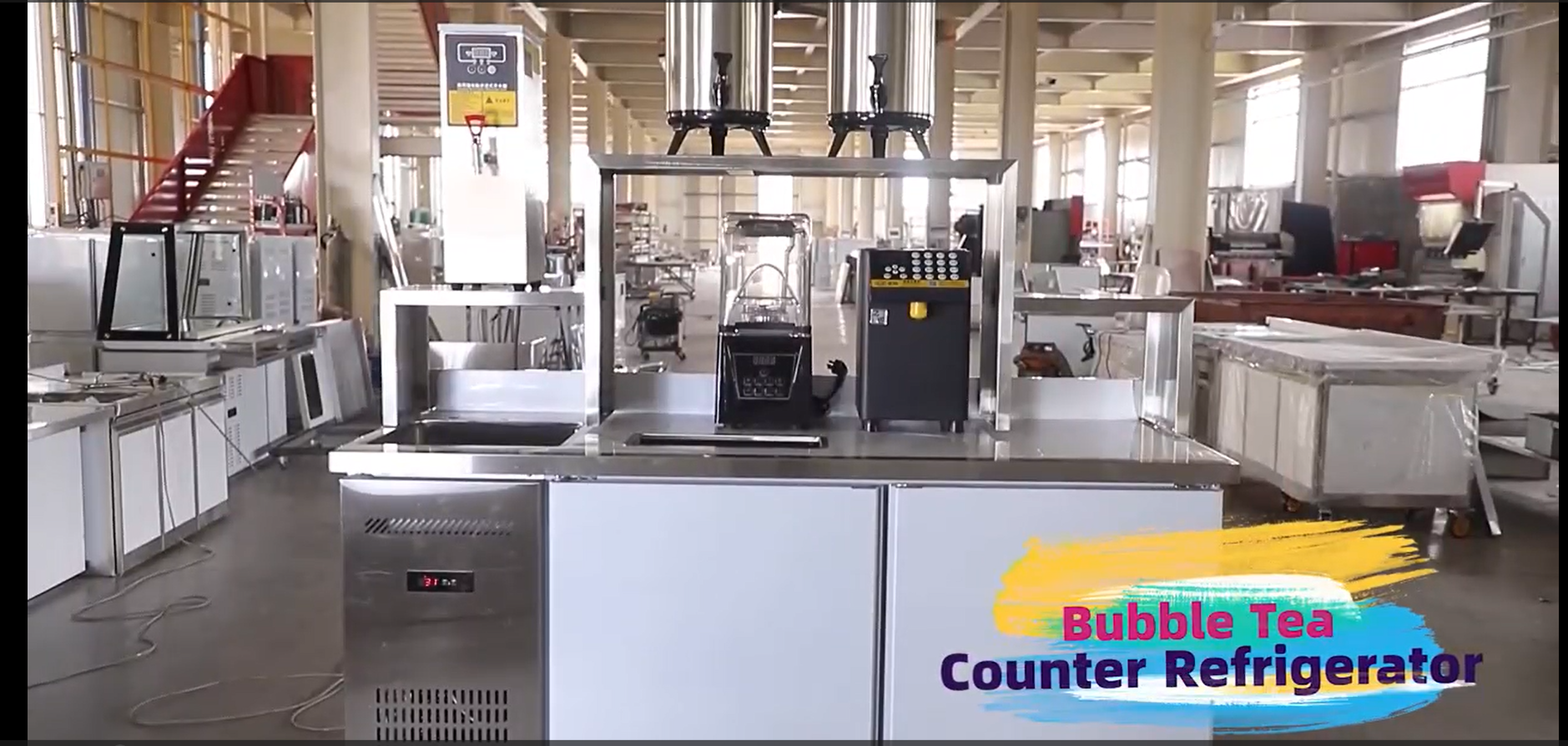

The water bar counter in this catering machinery factory is stacked in rows in the workshop, and the width in the back kitchen can be customized

Entering this nearly 1,000-square-meter workshop, a row of shiny stainless steel equipment immediately presents the "production capacity strength" - this is a manufacturing base specializing in catering machinery, from the water bar counter of a milk tea shop to the integrated operation counter of a fast food restaurant, each piece of equipment is born in accordance with the rhythm of a standardized production line. Food-grade 304 stainless steel is our "standard raw material" : it is welded with millimeter-level precision, the countertop is ground to be free of burrs and scratches, and even the gap between the cabinet doors is uniformly controlled within 2mm - after all, the frequent use in the kitchen of the catering industry leaves no room for compromise. The neatly stacked finished products wrapped in film in the workshop are the confidence for a monthly production of a thousand units. The equipment in the adjacent inspection area must pass three tests: "flatness of the countertop, load-bearing capacity of the cabinet door, and waterproof sealing performance" before it can be marked with the factory label. Whether it's a chain brand demanding 50 uniformly sized water bar counters or a single store owner looking for customized models that fit a 1.2-meter narrow kitchen, a flexible production line combined with in-stock reserves can ensure that urgent orders are delivered within 72 hours and customized models are available within one week. The reliability of this catering machinery factory lies in the fact that when you open a store, the kitchen equipment can not only save the cost of middlemen but also perfectly keep up with the opening rhythm.

Home

Home